CONTENTS

- INTRODUCTION TO BUILDING MATERIALS

- BUILDING STONES

- PROPERTIES OF STONES

- REQUIREMENTS OF STONES

- TESTS ON STONES

- STONE QUARRYING

- USES OF STONES

- COMMON BUILDING STONES

- BRICKS

- COMPOSITION OF GOOD BRICK EARTH

- HARMFUL INGREDIENTS IN BRICK EARTH

- MANUFACTURING OF BRICKS

- QUALITY OF GOOD BRICKS

- TESTING OF BRICKS

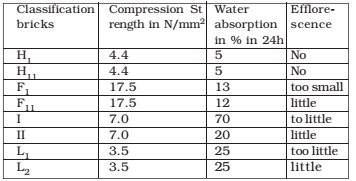

- IS CLASSIFICATION OF BRICKS

- SIZE AND WEIGHT OF BRICKS

- TYPES OF BONDING IN BRICK MASONARY

- CLAY PRODUCTS

- TIMBER

- DEFECTS IN TIMBER

- DEFECTS DUE TO NATURAL FORCES

- MARKET FORMS OF TIMBER

- GLASS

- TYPES OF GLASS

- THERMOPLASTICS AND ITS CHARACTERISTICS

- THERMOSETTING POLYMERS AND ITS CHARACTERISTICS

- ELASTOMERS

- STEELS

- IRON

- BITUMEN

Introduction to Building Materials

Any material which is used for construction purposes is known as building material. Many naturally occurring substances such as clay, rocks, sand and wood have been used since ages to construct buildings. Apart from naturally occurring materials, many man-made products are in use. Now we will discuss these different types of building materials.

BUILDING MATERIALS SSC JE STUDY MATERIAL PDF : CLICK HERE

BUILDING STONES

Stone is a naturally available building material which has been used from the early age of civilization. It is available in the form of rocks, which is cut to required size and shape and used as building block.

Classification of rocks:

(i) Geological classification: Based on the origin of formation, stones are classified into three main group :- Igneous, sedimentary and metamorphic rock.

- Igneous rocks: The inside portion of the earth’s surface has high temperature so as to cause fusion by heat at even ordinary pressures. The molten or pasty rocky material is known as the magma.This magma always tries to come out of the earth’s surface through cracks or fissures. The rocks which are formed by the cooling of magma once on earth surface after volcanic eruption are known as the igneous rocks.

- Sedimentary rocks: These rocks are formed by regular deposition of products of weathering on the pre-existing rock. Gravel, sandstone, limestone, lignite, gypsum etc. are examples of sedimentary rocks.

- Metamorphic rocks: Previously formed igneous and sedimentary rocks undergo changes due to metamorphic action of pressure and internal heat for e.g. due to metamorphic action granite becomes gneiss.

(ii) Physical classification: According to this classification, the rocks are of following types

- Stratified rocks: These rocks have layered structure or posess planes of stratification or cleavage. They can be easily split along these planes. E.g. Sand stone, lime stones, slate etc.

- Unstratified rocks: These rocks possess crystalline and compact grains. They can not be split along these planes. E.g. Granite, trap, marble etc.

- Foliated rocks: These rocks have a tendency to split along a definite direction only. The direction need not be parallel to each other as in the case of stratified rocks. This type of structure is very common in case of metamorphic rock.

(iii) Chemical classification: On the basis of their chemical composition, engineers prefer to classify rocks as:

- Silicious rocks: The main content of these rocks is silica. These are hard and durable. Eg. granite, trap etc.

- Argillaceous rocks: The main constituent of these rocks is argil i.e, clay. These rocks are hard and durable but brittle. Eg:- Slates, laterites.

- Calcareous rocks: The main constituent of these rocks is calcium carbonate. limestone is a calcareous rock of sedimentary origin while marble is a calcareous rock of metamorphic origin.

BUILDING MATERIALS MADE EASY GATE NOTES : CLICK HERE

PROPERTIES OF STONES

The following properties of the stone should be looked into before selecting them for engineering works

- Structure: The structure of the stone may be stratified or unstratified. Structured stone can easily be dressed hence, suitable for super structure. The unstratified stones are hard and difficult to dress. They are preferred for the foundation work.

- Texture: Fine grained stones with homogeneous distribution look attractive and hence they are used for carving. such stones are usually strong and durable.

- Density: Denser stones are stronger. Light weight stones are weak. Hence, stones with specific gravity less than 24 are considered unsuitable for building.

- Appearance: A stone with uniform and attractive colour is durable.

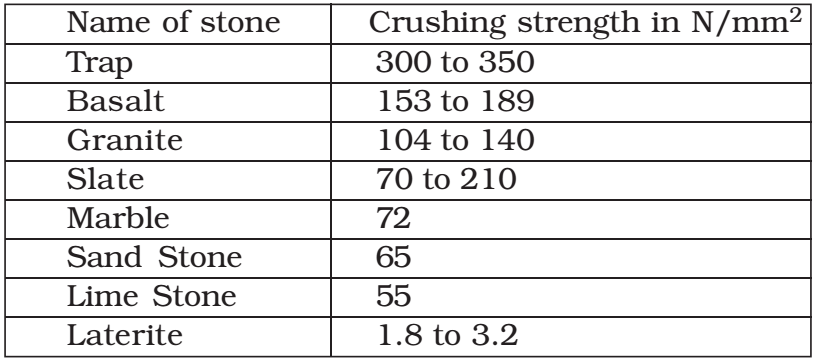

- Strength: Strength is an important property to be looked into before selecting stone as building block. Indian Standard code recommends, a minimum crushing strength of 3.5 N/mm2 for any building block.

- Hardness: It is an important property to be considered when stone is used for flooring and pavement. Coefficient of hardness is to be found by conducting test on standard specimen in Dory’s testing machine.

- Percentage wear: It is measured by attritiion test. It is an important property to be considered in selecting aggregate for road works and railway ballast. A good stone should not wear more than 2%.

- Seasoning: The stone obtained from quarry contains moisture in pores. The strength of stone improves if this moisture is removed before using the stone. The process of removing moisture from pores is called seasoning. The best way of seasoning is to allow it to the action of natural heat and wind effect for 6 to 12 months. This is very much required in the case of laterite stones.

REQUIREMENTS OF STONES

- Structure: The structure of stone may be stratified (layred) or unstratified structure. The selected stone should be easily dressed and suitable for super structure.

- Durability: Stone selected should be capable of resisting adverse effects of natural forces like wind, rain and heat. These factors can promote their fast weathering.

- Hardness: The stones used in floors and pavements should be able to resist abrasive forces caused by movement of man and material over them.

- Specific gravity: Heavier variety of stone should be used for the construction of dams, retaining walls, docks and harbours. The specific gravity of building stone is between 2.4 and 2.8.

- Porosity: Building stone should not be porous. If it is porous then rain water enters into the pores and reacts with stone and crumbles it.

IES MASTER GATE STUDY MATERIALS : CLICK HERE

COMMON BUILDING STONES

- Basalt and trap: The structure is medium to fine grained and compact. Their colour varies from dark grey to black. Fractures and joints are common. Their weight varies from 18KN/m3 to 29KN/m3. The compressive strength varies from 200 to 350 N/mm2.

- Granite: Granite are also igneous rocks. The colour varies from light grey to pink. The structure is crystalline, fine to coarse grained. They take polish well. and are hard durable. Specific gravity is from 2.6 to 2.7 and compressive strength is 100 to 250 N/mm2.

- Sand Stone: These are sedimentary rocks, and hence stratified. They consist of quartz and feldspar. They are found in various colour like white, grey, red, buff, brown, yellow and even dark grey.

- Slate: These are metamorphic rocks. Composed of quartz, mica and clay mineral. The specific gravity is 2.6 to 2.7. Compressive strength varies from 100 to 200 N/mm2.

- Laterite: It is metamorphic rock, having porous and spongy structure. Its specific gravity is 1.85 and compressive strength varies from 1.9 to 2.3 N/mm2. It can be easily quarried in blocks.

- Marbles: This is a metamorphic rock, that can take good polish. It is available in different pleasing colours-like white and pink. Its Specific gravity is 2.65 and compressive strength is 70-75 N/ mm2.

- Gneiss: It is a metamorphic rock. It has fine to coarse grains. Alternative dark and white bands are common. They are used in minor construction. The specific gravity varies from 2.5 to 3.0 and crushing

BRICKS

At places where stones are not easily available but suitable clay for the manufacture of bricks is available, in plenty. The bricks are the only alternative material of construction. The term brick refers to small units of building material, often made from fired clay and secured with mortar, a bonding agent comprising of cement, sand and water. A brick retains heat, with-stands corrosion and resists fire.

MANUFACTURING OF BRICKS

Preparation of Clay

Clay for the bricks is prepared in the following sequence:

- Unsoiling: It is the process in which top 200 mm of soil is thrown and is not used for manufacturing of bricks as it consists of majority of impurities in it.

- Digging: It is the process in which soil is dug out and spread over the level field to prepare it for next operation of cleaning.

- Cleaning: It is the process in which impurities like stones pebbles, organic matter, vegetative matter is removed from clay.

- Weathering: After cleaning the clay, it is exposed to the atmosphere for few weeks to few months for its softening/ripening/mellowing or weathering.

- Blending: It is the process in which different ingredients of the brick earth are spread over the weathered clay in definite proportion.

- Tempering: It is the process in which required degree of hardness is induced in the brick earth to make it suitable for the next operation of moulding.

Moulding

The process of giving desired shape and size to the bricks is termed as moulding. During moulding a mark of depth (10-20 mm) is placed over the surface of the brick, that is termed as frog mark. It serves two purposes,

- Used to indicate the trade name of the manufacturer.

- It acts as a key for the mortar where another layer of brick is placed over it.

- Quality of table moulded bricks is comparatively better than ground moulded bricks and its rate of moulding is also comparatively higher than ground moulded bricks.

ACE GATE STUDY MATERIALS : CLICK HERE

Drying

Moulded bricks if are directly burnt without drying are liable to get cracked due to excessive shrinkage, Hence, its drying is carried out before the burning operation in which the moisture content of the brick is reduced up to 2%. Drying of the bricks is carried out either naturally or artificially.

During drying, bricks are always placed along their edges and never along its face, in order to speed up to process of drying.

Burning

(The most important entire strength is developed here) because it imparts strength and hardness to the bricks. It makes them dense and durable. It should be done properly. As if bricks are over burned, they become brittle. Hence, they can be easily broken and if bricks are under burned, they remain soft and are not able to carry the design load. Burning of the bricks is carried out at 1100°C at which silica and lime fuse with each other thereby imparting strength to the bricks. Burning of the bricks is carried out either in clamps or hills.

BUILDING MATERIALS STUDY MATERIAL FOR RRB JE PDF CIVILENGGFORALL

DOWNLOAD LINK : CLICK HERE

PASSWORD : CivilEnggForAll

OTHER USEFUL BOOKS

- RAJASTHAN STAFF SELECTION BOARD (RSSB) JUNIOR ENGINEER DIPLOMA CIVIL ENGINEERING EXAM 2022 – HINDI & ENGLISH MEDIUM SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ISRO TECHNICAL ASSISTANT EXAM 2022 – CIVIL ENGINEERING – HINDI & ENGLISH MEDIUM – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- MADHYA PRADESH PUBLIC SERVICE (MPPSC) COMMISSION – ASSISTANT ENGINEER EXAM – MPPSC AE 2021 CIVIL ENGINEERING – SOLVED PAPER WITH EXPLANATIONS – PDF FREE DOWNLOAD

- BIHAR PUBLIC SERVICE COMMISSION (BPSC) ASSISTANT ENGINEER EXAM – 2022 – CIVIL ENGINEERING – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ODISHA PUBLIC SERVICE COMMISSION – OPSC AEE PANCHAYATI RAJ EXAM 2021 – SOLVED PAPER WITH EXPLANATION – FREE DOWNLOAD PDF