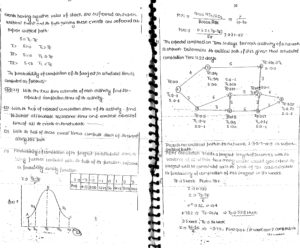

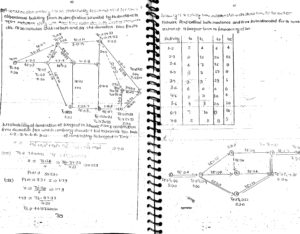

CPM & PERT

MADE EASY GATE HANDWRITTEN CLASSROOM NOTES

FREE DOWNLOAD PDF

CPM & PERT Made Easy GATE Handwritten Notes Free Download PDF of classroom notes. Also download Civil Engineering all subjects GATE Classroom notes PDF’s

CPM & PERT Made Easy GATE Handwritten Notes Free Download PDF

PLEASE NOTE : WE PROVIDE ONLY VERIFIED NOTES AND MATERIALS. ALL THE OTHER NOTES WHICH ARE AVAILABLE IN THE INTERNET WITH THE NAME MADE EASY CIVIL NOTES ARE FAKE AND ARE NORMAL CLASSROOM NOTES OF SOME COLLEGE. WE ALWAYS TRY TO BRING OUT QUALITY NOTES FOR FREE AND FOR THE SAKE OF STUDENTS WHO ARE REALLY WORKING HARD DAY AND NIGHT AIMING GOOD GATE/IES RANKS

Development of the Critical Path Method of Scheduling

In 1956, the E. I. DuPont de Nemours Company set up a group at its Newark, Delaware, facility to study the possible application of new management techniques to the company’s engineering functions.1 The planning and scheduling of construction projects was one of the first areas studied. The group had a UNIVAC I computer (the third unit built) at its disposal, and they decided to evaluate the potential of computers in scheduling construction work.

Mathematicians worked out a general approach; they theorized that if the computer was fed information on the sequence of work and the length of each activity, it could generate a schedule of work.2 In early 1957, the Univac Applications Research Center, under the direction of Dr. John W. Mauchly, joined the effort with James E.Kelley, Jr., of Remington Rand (UNIVAC) and Morgan Walker of DuPont in direct charge at Newark, Delaware. The original conceptual work was revised, and the resulting routines became the basic CPM. It is interesting that no fundamental changes in this first work have been made.

New Technique in CPM

In December 1957, a test group was set up to apply the new technique (then called the Kelley-Walker methods). The test team (made up of six engineers, two area engineers, a process engineer, and an estimator) and a normal scheduling group was assigned to plan the construction of a $10 million chemical plant in Louisville, Kentucky. As a control, the new scheduling team worked independently of the normal scheduling group. This is the only documented case of a comprehensive comparative CPM application. The test group had not been part of the development of the CPM method, but members were given a 40-hour course on the technique before starting the test. The network diagram for the project was restricted to include only the construction steps. The project was analyzed beginning with the completion of its preliminary design. The entire project was subdivided into major areas of scope, and each of the areas was analyzed and broken down into the individual work activities.

These activities were diagrammed into a network of more than 800 activities, 400 of which represented construction activities and 150 design or material deliveries. The ability of the first team was such that a larger-capacity computer program had to be developed for support. By March 1958, the first part of the network scheduling was complete. At that time, a change in corporate outlook, plus certain design changes, caused a 40 percent change in the plan of the project. Both planning groups were authorized to modify the plan and recompute schedules. The revisions, which took place during April 1958, required only about 10 percent of the original effort by the CPM test team, substantially better than the normal scheduling group. One significant factor involved the determination of critical delivery items. The normal scheduling group arbitrarily assigned critical categories, which the CPM group determined from its network analysis. From the analysis, it was determined that only seven items were critical, and three of these were not included in the normal scheduling group’s list.

The initial test scheduling was considered successful in all respects. In July 1958, a second project, valued at $20 million, was selected for test scheduling. It also was successfully scheduled. Since the first two projects were of such duration that the complete validity of the system could not be established, a shorter project, also at DuPont in Louisville, was selected for scheduling. The third project was a shutdown and overhaul operation involving neoprene, and one of the materials in the process was self-detonating, so little or no maintenance was possible during downtime. Although the particular maintenance effort had been done many times, it was considered to be a difficult test of the CPM approach. In the first CPM plan, the average shutdown time for the turnaround was cut from 125 to 93 hours, and in later CPM applications, it was further cut to 78 hours. The resultant time reduction of almost 40 percent far exceeded any expectations.

Development of the PERT Method of Scheduling

The development of CPM was enhanced when the U.S. Navy Polaris program became interested in it. The Polaris program staff had developed its own network system known as performance evaluation and review

technique (PERT). The DuPont work is considered antecedent material for the development of PERT. The Polaris fleet ballistic missile (FBM) system was initiated in early 1957. To manage the program, a Special Projects Office (SPO) was established under the direction of Admiral Raborn. The Office is generally credited with having developed the PERT system. One of the key people involved in the development of PERT was Willard Fazar, who noted that the various management tools available for managing the Polaris program did not provide certain information essential to effective program evaluation.

In particular, they did not furnish the following:

1. Appraisal of the validity of existing plans in terms of meeting program objectives

2. Measurement of progress achieved against program objectives

3. Measurement of potential for meeting program objectives

Comparison of CPM and PERT

The key difference between CPM and PERT is that one identifies activities of finite and reasonably estimated duration while the other identifies events of zero duration separated by “some form of activity” only loosely understood to be performed within a range of possible durations. This range of durations varies from an optimistic estimate (or shortest time until the next event will occur) to a “most likely” estimate to a pessimistic estimate.

This dichotomy was understandable since the duration of an activity, relating to a known quantity of work, was fairly capable of estimation; the duration between events, based upon a scope only vaguely understood, was much more a “guestimate.” The theory behind the PERT method was based upon the interplay between these estimates of duration and the statistical likelihood of a project outcome as the actual duration experienced may fluctuate among the three.The important distinction to remember, before considering the newer offshoots of CPM, is that CPM measures performance of defined activities and the durations of defined activities, while PERT measures the reaching of defined events and the passage of time between these events. Another important difference is that CPM durations are of defined events, while PERT durations are of undefined activity between events.

DOWNLOAD LINK : CPM & PERT Made Easy Handwritten Classroom GATE Notes Free Download PDF

PASSWORD : CivilEnggForAll

OTHER USEFUL LINKS FROM CIVILENGGFORALL

RCC MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

STRUCTURAL ANALYSIS MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

STRENGTH OF MATERIALS MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

STRENGTH OF MATERIALS (PART-1) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

STRENGTH OF MATERIALS (PART-2) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

HYDRAULIC MACHINERY MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

SURVEYING (PART-1) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

SURVEYING (PART-2) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

FLUID MECHANICS (PART-1) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

FLUID MECHANICS (PART-2) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

ENVIRONMENTAL ENGINEERING (PART-1) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

ENVIRONMENTAL ENGINEERING (PART-2) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

GEOTECHNICAL ENGINEERING (PART-1) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

GEOTECHNICAL ENGINEERING (PART-2) MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

RAILWAY ENGINEERING MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE

HIGHWAY ENGINEERING MADE EASY GATE HANDWRITTEN NOTES : CLICK HERE