CONTENTS

- Construction Materials

- Concrete

- The Principles of Proportioning

- Short-term and Long-term Properties of Concrete

- Bricks and Mortar

- Timber

- Bitumen

- Construction Management

- Analysis of Rates and Specifications

- Estimate

- Project Planning

- Elements of Network Diagram

- PERT (Programme Evaluation & Review Technique)

- CPM (Critical Path Method)

- Float (F)

CONSTRUCTION MATERIALS

Structural Steel

In order to reduce the work involved in design computations, and to facilitate the use of the Indian Standard Code of Practice for Use of Structural Steel in General Building Construction [IS: 800-2007 (Revised)], it is proposed to make available a number of design handbooks showing typical designs of different types of structures. Structural steel can be in the form of rolled steel, beam, channel and angle sections, metal strip, sheet, bars (round and square), flats and plate, tee bars, bulb angles. A no. of design codes are available according to the shape of the structural steel member.

Composition of Structural Steel

Steel is an alloy of Iron, Carbon, Chromium, Nickel and many other elements. Following is a list of some important chemical elements used in structural steels:

- Carbon (C): It is the most important chemical element in steel. If the carbon content in the alloy is increased to a certain level then strength increases but ductility decreases. So, Structural steels, should have carbon contents between 0.15 to 0.30%; if the carbon content goes much higher, the ductility will be too low, and for magnitudes less than 0.15% the strength will not be satisfactory.

- Manganese (Mn): Manganese has a percentage ranging from about 0.50 to 1.70%. It has effects similar to those of carbon, and the steel producer uses these two elements in combination to obtain a material with the desired properties. Manganese is a necessity for the process of hot rolling of steel by its combination with oxygen and sulphur.

- Aluminium (Al): Aluminium is used as a deoxidizer in the material, and also helps to form a more fine-grained crystalline microstructure.

- Chromium (Cr): It is primarily used to increase the corrosion resistance of the material, and for that reason often occurs in combination with nickel and copper. Stainless steel contains 18% of nickel and 8% of chromium.

- Copper (Cu): Copper is another primary corrosion resistance elements. It is typically found in amounts not less than 0.20%, and is the primary anti-corrosion component in steel grades.

- Molybdenum (Mo): It increases the strength of the steel at higher temperatures and also improves corrosion resistance. Molybdenum has effects similar to manganese and vanadium, and is often used in combination with one or the other.

- Nickel (Ni): It enhances the corrosion resistance of steel, and also the low-temperature behaviour of the material by improving the fracture toughness.

- Silicon (Si): Along with aluminium, silicon is one of the principal deoxidizers for structural steel. It normally appears in amounts less than 0.40%.

IES MASTER CIVIL ENGINEERING GATE STUDY MATERIALS PDF: CLICK HERE

Material Properties of Steel

Properties of the steel depends upon its chemical composition, method of manufacture and process of fabrication. Some important properties of steel which are desired for its use as a structural material are:

- Strength: Tensile strength increases with increased hardness of the material.

- Toughness: It is the resistance to the impact loading against fracture. It is in the nature of all materials to contain some imperfections. In steel these imperfections take the form of very small cracks. If the steel is insufficiently tough, the ‘crack’ can propagate rapidly, without plastic deformation and result in a ‘brittle fracture’. The risk of brittle fracture increases with thickness, tensile stress, stress raisers and at colder temperatures. The toughness of steel and its ability to resist brittle fracture are dependent on a number of factors that should be considered at the specification stage.

- Ductility: It is a measure of the degree to which a material can be strained or elongated between yield point to the fracture point under the effect of tensile loading. With the increase in carbon content of the steel, its strength increases but ductility decreases. Ductility is measured in tension tests by percent elongation over a given gauge length usually 2 or 8% reduction of cross-sectional area. Ductility is an important property because it permits redistribution of stresses in continuous members and at points of high local stresses.

- Durability: The ability to withstand wear and tear through weathering and corrosive attack etc. is referred as durability of steel. The increased distortion of planes and structure decreases the corrosion resistance of the material.

Behaviour of Structural Steel

Structural steel has different behaviour under different conditions. If the material is subjected to compression like in columns, it behaves differently as compared to its behaviour under tensile stresses. Steel columns are slender because of high strength of the material. As the compressive stress is gradually increased, a value is reached at which the column, instead of just axially shortening in length, buckles and deforms perpendicular to its axis. This value of load is called the buckling load. When a column reaches the buckling load, it has effectively failed as a structural element and is incapable of sustaining the load.

The structural steel, when used as a beam element, is represented by internal forces called bending moments and shear forces. The behaviour is characterized by the magnitude and distribution of these forces. At any point in the beam, the internal shear force and the internal bending moment can be represented as pairs of forces.

ACE ACADEMY CIVIL ENGINEERING GATE STUDY MATERIALS PDF: CLICK HERE

Concrete

Constituents

Concrete a composite man-made material, is the most widely used material in the construction industry. It consists of a rationally chosen mixture of binding material such as lime or cement, well graded fine and coarse aggregates, water and admixtures (to produce concrete with special properties). In a concrete mix, cement and water form a paste or matrix which in addition to filling the voids of the fine aggregate, coats the surface of fine and coarse aggregates and binds them together. Freshly mixed concrete before set is known as wet or green concrete whereas after setting and hardening it is known as set or hardened concrete. The moulded concrete mix after sufficient curing becomes hard like stone due to chemical action between the water and binding material.

A good quality concrete is essentially a homogeneous mixture of cement, coarse and fine aggregates and water which consolidates into a hard mass due to chemical action between the cement and water. Each of the four constituents has a specific function. The coarser aggregate acts as a filler. The fine aggregate fills up the voids between the paste and the coarse aggregate. The cement in conjunction with water acts as a binder. The mobility of the mixture is aided by the cement paste, fines and nowadays, increasingly by the use of admixtures.

Water-cement ratio

The water-cement ratio (w/c) is one of the major factors but not the only one influencing the strength of concrete. It is responsible mainly for the porosity of the hardened cement paste. Water-cement ratio is the water used to the quantum of cement in the mixture by weight. For proper workability the w/c ratio varies from 0.4-0.6. However, maximum strength is derived at w/c = 0.4 at which minimum capillary cavities are expected to form. It may be noted that for complete hydration of cement under controlled conditions the water requirement is about 38 per cent.

Concrete Mix Design

Conventional nominal mix proportioning (1:1:2; 1:2:4; 1:3:6, etc.) have limited significance as these are with little consideration for the materials that will be used. Since the quantity of fine aggregate is fixed irrespective of the cement and the maximum size of aggregate, considerable variations in quality are obtained by this method. Therefore, nominal mix proportions, arbitrarily fixed, have little use in concrete mix design. Another reason for increased use of the design mix concept is that the water-cement ratio is not specified for nominal mixes, and has to be kept as low as possible provided that the mix is fully compacted concrete. Mix design should ensure that the concrete:

- complies with the specifications of structural strength laid down, which is usually stated in terms of the compressive strength of standard test specimens.

- fulfils the durability requirements to resist the environment in which the structure will serve throughout its functional life.

- has capability of being efficiently mixed, transported and compacted

Concrete mix proportions can be expressed in terms of volume or weight. The present trend is towards specifying mixes in terms of minimum strength requirements, rather than by volume proportions. For example, M20 design mix should have a characteristic strength of 20 N/mm2, M25 mix shall have a characteristic strength of 25 N/mm2, etc.

MADE EASY CIVIL ENGINEERING GATE NOTES PDF: CLICK HERE

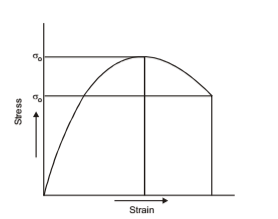

Stress Strain Curve of Concrete

The true elastic curve for concrete in compression can be plotted by applying and o releasing load until the set at zero loads becomes constant. By subtracting the set from the total deformation the elastic deformation for a given load is determined. Since mortar and concrete have no elastic limit, the modulus of elasticity for concrete must be the slope of the stress deformation curve at zero stress. The elastic modulus of concrete in compression, Ec = 5000fck, where fck is the characteristic strength of concrete. The elastic modulus of concrete varies from 14 x 103 to 40 x 103 N/mm2. Its value increases with the density and to some extent with age.

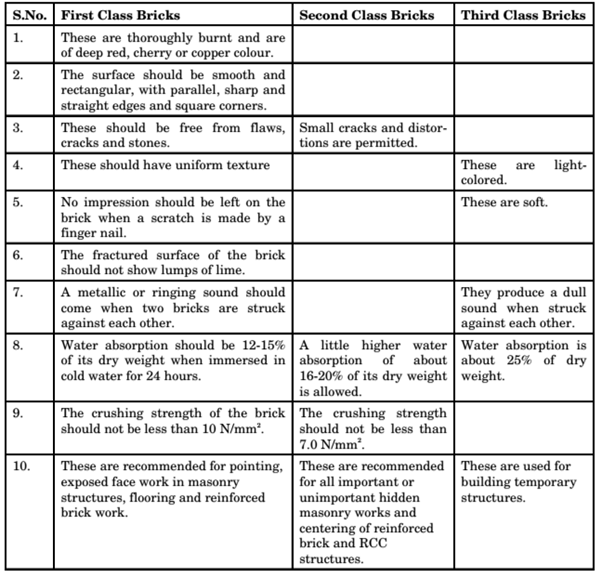

Classification of Bricks

Clay bricks are classified as first class, second class, third class and fourth class based on their physical and mechanical properties.

Characteristics of Good Brick

The essential requirements for building bricks are sufficient strength in crushing, regularity in size, a proper suction rate, and a pleasing appearance when exposed to view.

- The bricks should have uniform size and plane, rectangular surfaces with parallel sides and sharp straight edges.

- The brick should have a uniform deep red or cherry colour as indicative of uniformity in chemical composition and thoroughness in the burning of the brick.

- The surfaces should not be too smooth to cause slipping of mortar.

- The brick should have pre-compact and uniform texture. A fractured surface should not show fissures, holes grits or lumps of lime.

- The brick should be so hard that when scratched by a finger nail, no impression is made.

- When two bricks are struck together, a metallic sound should be produced.

- Water absorption should not exceed 20% of its dry weight when kept immersed in water for 24 hours.

- Crushing strength should not be less than 10 N/mm2.

- Raw material should be free from stones, kankars, organic matter, saltpetre, etc.

Ingredients of Good Brick

- Silica 50-60%

- Alumina 20-30%

- Lime 10%

- Magnesia < 1%

- Less than 20%

- Ferric oxide < 7%

- Less than 20% Alkalis < 10%

- Less than 20%

- Carbon dioxide Very small percentage

- Water Very small percentage

CONSTRUCTION MATERIALS AND MANAGEMENT CIVIL ENGINEERING GATE 2020 STUDY MATERIAL FREE DOWNLOAD PDF

DOWNLOAD LINK : CLICK HERE

PASSWORD : CivilEnggForAll

OTHER USEFUL BOOKS

- CIVIL ENGINEERING TEXTBOOKS WITH DOWNLOAD LINKS

- IES MASTER CIVIL ENGINEERING GATE STUDY MATERIALS PDF

- ACE ACADEMY CIVIL ENGINEERING GATE STUDY MATERIALS PDF

- RAJASTHAN STAFF SELECTION BOARD (RSSB) JUNIOR ENGINEER DIPLOMA CIVIL ENGINEERING EXAM 2022 – HINDI & ENGLISH MEDIUM SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ISRO TECHNICAL ASSISTANT EXAM 2022 – CIVIL ENGINEERING – HINDI & ENGLISH MEDIUM – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- MADHYA PRADESH PUBLIC SERVICE (MPPSC) COMMISSION – ASSISTANT ENGINEER EXAM – MPPSC AE 2021 CIVIL ENGINEERING – SOLVED PAPER WITH EXPLANATIONS – PDF FREE DOWNLOAD

- BIHAR PUBLIC SERVICE COMMISSION (BPSC) ASSISTANT ENGINEER EXAM – 2022 – CIVIL ENGINEERING – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ODISHA PUBLIC SERVICE COMMISSION – OPSC AEE PANCHAYATI RAJ EXAM 2021 – SOLVED PAPER WITH EXPLANATION – FREE DOWNLOAD PDF