CONTENTS

- Cement Concrete

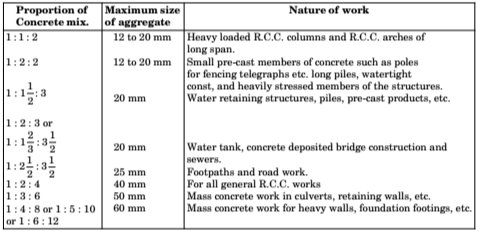

- Recommended Mixes Of Concrete

- Estimating Yield Of Concrete

- Types Of Cement

- Aggregates

- Properties And Tests On Concrete

- Fineness Modulus And Water Cement

- Ratio Method

- Acceptance Criteria

CEMENT CONCRETE

The cement concrete is a mixture of cement, sand, pebbles or crushed rock and water, which when placed in the skeleton of forms and allowed to cure, becomes hard like a stone.

Properties of Cement Concrete:

- It has high compressive strength.

- It is free from corrosion and there is no appreciable effect of atmospheric agents on it.

- It hardens with age and the process of hardening continues for a long time after the concrete has attained sufficient strength.

- It is proved to be more economical than steel.

- It binds rapidly with steel and as it is weak in tension, the steel reinforcement is placed in cement concrete at suitable places to take up the tensile stresses. This is termed as the R.C.C.

- Under the following two conditions, it has

a tendency to shrink

- There is initial shrinkage of cement concrete which is mainly due to loss of water through forms, absorption by surface of forms, etc.

- The shrinkage of cement concrete occurs as it hardens, the tendency of cement concrete can be minimised by proper caring of concrete.

- It forms a hard surface, capable of resisting abrasion.

- Its final strength and quality depend entirely on local conditions and persons handling it.

IES MASTER GATE CIVIL ENGINEERING STUDY MATERIALS PDF: CLICK HERE

MATERIALS USED FOR R.C.C. WORK

- Cement

- Aggregates

- Steel

- Water

- The material which is passed through BIS test sieve no. 480 is termed as fine aggregate. Usually, the natural river sand is used as a fine aggregate.

- The material which is retained on BIS test sieve no. 480 is termed as a coarse aggregate. The broken stone is generally used as a coarse aggregate.

- For thin slabs and walls, the maximum size of coarse aggregate should be limited to one-third the thickness of concrete section.

- It may be noted that sometimes ingredients other than above are added in concrete to give it certain improved qualities or for changing different physical properties in its fresh and hardened stages. These ingredients or substances are known as the admixtures. The addition of an admixture may improve the concrete with respect to its strength, hardness, workability, water resisting power etc.

Commonly used Admixtures:

Alum, Al2(SO4)3, BaO, bitumen, CaCl2, Coal ash, common salt, iron oxide, lime, mineral oil, organic oils, KCl, silicate of soda, tar products, volcanic ashes, ZnCl2 etc. For instance, when calcium chloride (CaCl2) is added as admixture, it absorbs water from the concrete and w/c ratio falls down and can even be brought down up to the limit of 0.25. Thus, it gives quick setting concrete. However the use of calcium chloride is not suitable for concrete with reinforcing bars.

Depending upon their respective activities in the concrete mix, the admixtures can be classified in the following five categories:

- Accelerators

- Air entraining admixtures

- High range of water reducers or super plasticisers

- Normal range of water reducers or plasticisers, and

- Retarders.

ACE CIVIL ENGINEERING GATE STUDY MATERIALS PDF: CLICK HERE

Advantages from their (i.e. admixtures) use:

- Adjusting the final setting times of concrete.

- Higher early and ultimate strength.

- Higher slump and self-travelling concrete.

- Increasing durability of concrete.

- Lesser water cement ratios.

- Reducing quantity of cement.

- Reducing permeability of the concrete etc.

Sea Water for making Concrete

All chlorides tend to accelerate the setting of cement and to improve the strength of concrete in early stages. On the other hand, the sulphates tend to retard the setting of cement and to discourage the strength of concrete in early stages. The sea water tends to develop dampness and efflorescence. Hence, it can be adopted for concrete structures where finishing characteristics are not important or where persistent dampness of surface is permissible. It is found that the sea water does not lead to corrosion of reinforcement, provided the concrete is dense and there is enough cover to the reinforcement. The minimum cover over the reinforcement should be 75 mm. The sea water should not be used for making prestressed concrete.

Proportioning Concrete

The process of selection of relative proportions of cement, sand, coarse aggregate and water, so as to obtain a concrete of desired quality is known as the proportioning of concrete. The proportions of coarse aggregate, fine aggregate, cement and water should be such that the resulting concrete has the following properties:

- When concrete is fresh, it should have enough workability so that it can be placed in the formwork economically.

- The concrete must possess maximum density or in other words, it should be the strongest and most water-tight.

- The cost of materials and labour required to form concrete, should be minimum.

Workability

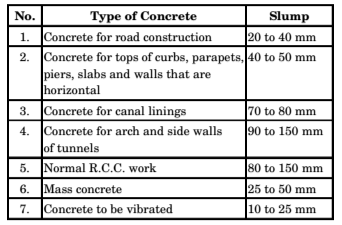

The term workability may be defined as the case with which concrete may be mixed, handled, transported, placed in position and comparted. According to Indian standard, workability of concrete is that property of concrete which determines the amount of internal work necessary to produce full compaction. Several tests which have been developed to measure the workability of concrete are:

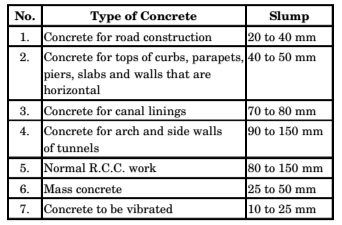

- Slump test

- Compaction factor test

- Vee-Bee test, and

- Vibro-workability test.

MADE EASY CIVIL ENGINEERING GATE NOTES PDF: CLICK HERE

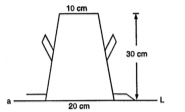

Slump Test

Diameter of the rod is 16 mm. and its length is 60 mm. The strokes are given for ramming vary from 20 to 30. The cone is then gradually raised vertically and removed. Then the concrete is allowed to subside and then, height of concrete is measured. The slump of concrete is obtained by deducting height of concrete after subsidence from 30 cm.

The important facts regarding workability:

- If more water is added to attain the required degree of workmanship, it results into concrete of low strength and poor durability.

- If the strength of concrete is should not be affected, the degree of workability can be obtained:

- by slightly changing the proportions of fine and coarse aggregates, in case the concrete mixture is too wet; and

- by adding a small quantity of water-cement paste in the proportion of original mix, in case concrete mixture is too dry.

- A concrete mixture for one work may be prove to be too stiff or too wet for another work. For instance, the stiff concrete mixture will be required in case of vibrated concrete work while wet concrete mixture will be required for thin section containing reinforcing bar.

- The workability of concrete is affected mainly by water content, water-cement ratio and aggregate cement ratio.

- The workability of concrete is also affected by the grading, shape, texture and maximum size of the coarse aggregates to be used in the mixture

CONCRETE TECHNOLOGY STUDY MATERIAL FOR SSC JE PDF CIVILENGGFORALL

DOWNLOAD LINK : CLICK HERE

PASSWORD : CivilEnggForAll

OTHER USEFUL BOOKS

- TELANGANA STATE PUBLIC SERVICE COMMISSION – ASSISTANT ENGINEER 2023 – TSPSC AE 2023 CIVIL ENGINEERING EXAM SOLVED PAPER WITH EXPLANATIONS PDF FREE DOWNLOAD

- SSC JE 2023 CIVIL ENGINEERING (CPWD/CWC/MES) EXAM SOLVED PAPER PDF FREE DOWNLOAD

- BIHAR PUBLIC SERVICE COMMISSION ASSISTANT ENGINEER (BPSC AE) 2022 CIVIL ENGINEERING EXAM SOLVED PAPER WITH EXPLANATIONS PDF

- NHPC (NATIONAL HYDROELECTIC POWER CORPORATION) JUNIOR ENGINEER NHPC JE 2022 CIVIL ENGINEERING EXAM SOLVED PAPER PDF FREE DOWNLOAD

- ANDHRA PRADESH PUBLIC SERVICE COMMISSION (APPSC) – ASSISTANT EXECUTIVE ENGINEER (AEE) EXAM 2022 – SOLVED PAPER FREE DOWNLOAD PDF