CONTENTS

- GEOMETRIC DESIGN OF HIGHWAYS

- SIGHT DISTANCES

- HORIZONTAL CURVES

- SUPER ELEVATION

- EXTRA WIDENING

- TRANSITION CURVES

- SETBACK DISTANCE

- GRADE COMPENSATION

- LENGTH OF VERTICAL CURVES

- TESTING AND SPECIFICATIONS OF PAVING MATERIALS

- BITUMINOUS MATERIALS

- TYPES OF BITUMEN

- CUTBACK BITUMEN

- BITUMINOUS EMULSION

- DESIGN OF PAVEMENTS

- DESIGN FACTORS

- DESIGN OF RIGID PAVEMENT

- TRAFFIC CHARACTERISTICS

- EFFECTS OF DIMENSION OF VEHICLE

- TRAFFIC STUDY

- PASSENGER CAR UNITS

- CAPACITY FLOW

- CONFLICT POINTS AT AN INTERSECTION

- ACCIDENT STUDY

- PARKING STUDY

- ROTARY INTERSECTION

- TRAFFIC SIGNS

- PROBLEMS AND SOLUTIONS

Highway cross-section elements:

Pavement Surface Characteristics:

(i) Friction (Skid resistance):

- It is used to calculate design speed, radius of curves, super elevation, sight distances, etc.

- Two phenomena occurring due to friction are skid and slip. Skid occurs when wheel moves without rotating. Slip occurs when wheel rotates more than its corresponding longitudinal distance.

- Frictional resistance along the direction of movement of wheel is called longitudinal frictional resistance and perpendicular to it is known as lateral frictional resistance.

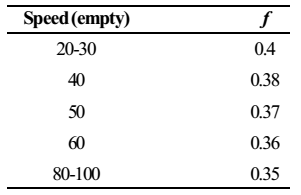

- IRC recommends coefficient of longitudinal friction as 0.35 to 0.40 and coefficient of lateral friction as 0.15.

- Frictional resistance decreases with temperature, wear and tear of tyre, tyre pressure, load, smoothness of pavement and wetness of pavement.

(ii) Pavement unevenness:

- It is the cumulative measure of vertical unduraturn of pavement surface recorded per unit horizontal distance of road.

- It is measured by bump indicator or roughometer and is expressed in terms of unevenness index and unit is usually cm/km.

- Lesser the value, better the pavement.

- For good pavements, it should be 150 cm/km and 250 cm/km is considered satisfactory.

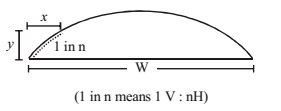

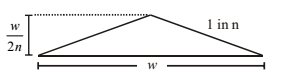

Camber or Cross-slope:

- It is the slope provided along transverse direction for drainage of rain water from road surface and preventing from seepage to layers below surface and water logging.

- It is expressed as 1 in n or as percentage.

- Depending on shape it can be parabolic, elliptic, straight line or combination of straight line and parabolic.

HIGHWAY ENGINEERING IES MASTER GATE STUDY MATERIAL PDF: CLICK HERE

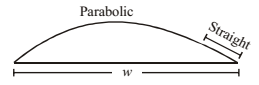

Parabolic/Elliptical Camber

- most preferred

- good for fast-moving traffic

Straight Line Camber

- preferred for cement concrete pavement.

- used when divider is there at the centre of road or on curved road.

Combination of Straight line and Parabolic Shape

- has advantages of both parabolic and straight roads.

- useful to increase contact area of wheel.

- parabolic at centre and straight at both sides.

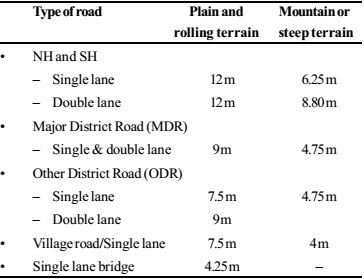

Width of pavement or carriage way:

- Width of pavement depends on width of each lane and number of lanes.

- Number of lanes depends on predicted traffic volume and capacity of each lane.

- Maximum width of vehicles as per IRC is 2.44 m.

TRANSPORTATION ENGINEERING ACE ACADEMY GATE STUDY MATERIAL PDF: CLICK HERE

Road margins:

Various elements of margins are:

- Shoulders: Provided to serve as an emergency lane. Minimum width recommended is 2.5 m.

- Frontage roads

- Drive ways

- Parking lane

- Footpath

- Guard rail etc.

Width of road way or formation: Formation width = carriage way width including separations, if any + shoulder.

Right of way:

- Area acquired for road, along its alignment. It depends on the number of lanes, importance of road and future development. Right of way = Formation width + Road margins.

- NH and SH: Normal width = 45 m Maximum width = 60 m

- Distance between: Building line = 80 m Control line = 150 m

TRANSPORTATION ENGINEERING ACE ACADEMY GATE NOTES PDF: CLICK HERE

Tests on Bitumen:

- Penetration Test: It is used to determine hardness or consistency of bituminous materials. The distance traversed by standard needle in the bituminous materials is measured in 1/10th of a millimeter. Grading of bitumen is done by this value, e.g. 80/100 means penetration value of bitumen is between 80 and 100. At hot climate 30/40 is preferred.

- Ductility Test: It is expressed as distance in ‘cm’ to which a standard briquette of bitumen can be stretched before it breaks. Rate of pull: 50 mm/min or 5 cm/min. This test measures elasticity and adhesiveness of bitumen. The ductility value usually varies from 5 cm to 100 cm. Desirable value: 50 cm.

- Viscosity Test: It is used to specify the consistency of bitumen. Viscosity is the resistance of flow of the fluid. It is measured by orifice type viscometer. It is determined by measuring number of seconds required for 50 ml of material to flow through standard orifice.

- Float Test: It is also used to measure consistency. Float test value is determined by measuring time taken in seconds by water to force its way into the float through the bitumen plug. Higher the value, stiffer the material.

- Softening Point Test: It is the temperature at which a substance attains a particular degree of softening under standard test conditions. It is usually measured by Ring and Ball test. For high grade bitumen, softening point will be higher and penetration value will be lesser. Bitumen of higher softening point is preferred in warm climate areas.

- Specific Gravity Test: Specific gravity is determined by a pycnometer. Pure bitumen has specific gravity values ranging from 0.97 to 1.02. Cutback bitumen usually has lower specific gravity. Jar has specific value ranging from 1.10 to 1.25.

- Flash and Fire Point Test: It is measured by Pensky– Martens apparatus. Flash point is the lowest temperature at which vapour of a substance momentarily catches fire in form of flash. The minimum specified flash point value of bitumen is 175°C. Fire point is the lowest temperature at which the application of test flame causes the material to ignite and burn at least for 5 seconds under specified conditions.

- Spot Test: It is used to determine overheated or cracked bitumen. Naptha solution is used for this test.

- Loss on Heating Test: Bitumen is heated to 163°C for 5 hours. The specified value for bitumen used for pavement mixes is that it should not be more than 1%.

- Solubility Test: Pure bitumen is completely soluble in carbon disulphide (CS2) and carbon tetrachloride (CCl4). Solubility is measured as percentage of original sample that dissolves in these solvents. In test with CCl4, bitumen is considered to be cracked if blank residue is more than 0.5%. In test with CS2, minimum proportion of bitumen soluble should be 99%.

- Water Content Test: Minimum water content in bitumen should be less than 0.2% by weight.

HIGHWAY ENGINEERING STUDY MATERIAL FOR SSC JE PDF CIVILENGGFORALL

DOWNLOAD LINK : CLICK HERE

PASSWORD : CivilEnggForAll

OTHER USEFUL BOOKS

- BUILDING MATERIALS – MOCK TEST 1 (QUICK)

- TELANGANA STATE PUBLIC SERVICE COMMISSION – ASSISTANT ENGINEER 2023 – TSPSC AE 2023 CIVIL ENGINEERING EXAM SOLVED PAPER WITH EXPLANATIONS PDF FREE DOWNLOAD

- SSC JE 2023 CIVIL ENGINEERING (CPWD/CWC/MES) EXAM SOLVED PAPER PDF FREE DOWNLOAD

- BIHAR PUBLIC SERVICE COMMISSION ASSISTANT ENGINEER (BPSC AE) 2022 CIVIL ENGINEERING EXAM SOLVED PAPER WITH EXPLANATIONS PDF

- NHPC (NATIONAL HYDROELECTIC POWER CORPORATION) JUNIOR ENGINEER NHPC JE 2022 CIVIL ENGINEERING EXAM SOLVED PAPER PDF FREE DOWNLOAD

Leave a Reply