CONTENTS

EXERCISES, SOLVED PROBLEMS, HINTS AND SOLUTIONS OF THE BELOW TOPICS

- Highways

- Highway Geometric Design

- Sight Distance

- PIEV Theory

- Design of Horizontal Alignment

- Design of Vertical Alignment

- Highway Material

- Testing and Specification of Paving

- Materials

- Tests on Road Aggregates

- Bituminous Materials

- Tar

- Cement

- Standard Tests

- Design of Highway Pavements

- Design of Rigid Pavements

- Traffic Parameters

- Environmental Parameters

- Foundation Strength

- Foundation Surface Characteristics

- Concrete Characteristic Pavement

- Modulus of Elasticity (E) and Poisson’s Ratio

- Coefficient of Thermal Expansion

- Design of Slab Thickness

- Calculation of Stresses

- Design of Joints

- Design of Dowel Bars

- Geometrical Design of Railway Track

- Radius of Curve/Degree of Curve (D°)

- Versine of Curve

- Super Elevation (Cant)

- Equilibrium Cant (for Equilibrium Speed)

- Cant Deficiency (D)

- Runaway Length

- Balanced Field Concept

- Taxiway

- Exit Taxiway

- Traffic Engineering

BITUMINOUS MATERIALS

Bituminous binders used in pavement construction works include both bitumen and tar. Bitumen is a petroleum product obtained by distillation of petroleum crude whereas road tar is obtained by destructive distillation of coal or wood. Both bitumen and tar have similar appearance black in colour though they have different characteristics. Both these materials can be used for pavement works.

Bitumen It is a hydrocarbon material of either natural or pyrogeneous origin, found in gaseous, liquid, semisolid or solid form and is completely soluble in carbon disulphide and in carbon tetra chloride. Bitumen is a complex organic material and occurs either naturally or may be obtained artificially during distillation of the petroleum. Bituminous materials are very commonly used in highway construction because of their binding and their water proofing properties.

When bitumen contains some inert materials or minerals; it is sometimes called asphalt. Asphalt is found as deposits in the form of natural asphalt or rock asphalt. Bitumen is classified as follows

- Asphaltic Bitumen

- Fluxed native asphalt

IES MASTER CIVIL ENGINEERING GATE STUDY MATERIALS PDF: DOWNLOAD LINK

ACE ACADEMY CIVIL ENGINEERING GATE STUDY MATERIALS PDF: DOWNLOAD LINK

Requirements of Bitumen

- Viscosity of the bitumen at the time of mixing and compaction should be adequate. This is achieved by heating the bitumen and aggregate prior to mixing or by use of cutbacks or emulsions of suitable grade.

- Bituminous material should not be highly temperature susceptible. During hottest weather of the region, bituminous mix should not become too soft or unstable. During cold weather, bituminous mix should not become too hard and brittle, causing cracking of surface. The material should be durable.

- In presence of water, the bitumen should not strip off from the aggregate. There has to be adequate affinity and adhesion between bitumen and the aggregate used in the mix.

Cut-back Bitumen

This is a liquid binder obtained by blending a bituminous binder with a volatile solvent. Itis suitable for direct application and manipulation in road construction. The solvent used serves as a substitute for heat and helps in increasing liquifying effect over a larger period of time. Behaviour of a cut back bitumen in any particular situation depends upon character and amount of solvent present.

Bitumen Emulsion

Emulsion is a mixture of two immiscible liquids. Mixing is done in the presence of emulsifying agent such as resin or soap, which helps in mixing the two liquids. Types: Bitumen emulsions are of following two types:

- In which minute bubbles of bitumen are dispersed in water.

- Which consists of a bitumen-water mixture in which up to about 10% of water forms dispersed phase and cut back bitumen is the continuous phase. This type is also called inverted emulsion.

Tests on Bitumen

Penetration Test

This test determines hardness or softness of bitumen by measuring depth in lenths of a millimeter to which a standard loaded needle will penetrate vertically in five seconds. Sample is maintained at a temperature of 25oC. Penetrometer consists of needle assembly with a total weight of 100g and device for releasing and locking in any position. There is a graduated dial to read penetration values to 1/10th of a millimeter. Bitumen grade is specified in terms of penetration values. 80-100 or 80/100 grade bitumen means penetration value of the bitumen in the range 80-100 at standard test conditions. Range of penetration value used in pavement construction is 20-225.Generally 30/40 and 80/100 grade bitumen are used depending upon construction type and climatic condition. 2.

Tests for Ductility

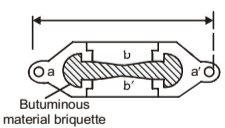

Ductility of a material is its property to elongate when subjected to tension before breaking. Ductility of bitumen is expressed as the distance in centimeters to which a standard briquette of bitumen can be stretched before the thread breaks.

Apparatus: Brass mould placed on a brass plate. Dimension of the Mould are as follows:

- Total length = 7.45 to 7.55 cms

- Maximum width = 2.97 to 3.03 cms.

- Width at the mouth of the clip = 1.98 to 2.02 cms.

- Width at the minimum cross-sections (i.e. half way between clips) = 0.99 to 1.01 cms.

- Thickness = 0.99 to 1.01 cms

Procedure

- Test specimen after prepared by moulding is kept at a constant temperature of 25C in a water bath for a period of 85 to 95 minutes.

- Birquette is removed from the plate, side pieces detached and the sample is tested by pulling clips at the ends, placed in the ductilometer. Two clips are pulled at the rate of 5 cm/minute, until rupture.

- Distance in cms that the briquette stretches before breaking gives ductility of the material.

Note: Ductility value of bitumen vary from 5 to 100 for different bitumen grades. A minimum ductility value of 75 cm has been specified by the ISI for bitumen of grades 45 and above, obtained from sources other than Assam petroleum (i.e. S45 and above), the minimum ductility value may be 50 cm for bitumen of grade S35, obtained from these sources.

ACE ACADEMY CIVIL ENGINEERING GATE HANDWRITTEN CLASSROOM NOTES PDF: DOWNLOAD LINK

MADE EASY CIVIL ENGINEERING GATE HANDWRITTEN CLASSROOM NOTES PDF: DOWNLOAD LINK

Softening Point Test

Bitumen is a non crystalline solid or viscous material having adhesive properties derived from petroleum either by natural or refinery process. In residual transition of asphaltic bitumen from solid to liquid state, it is not possible to determine exactly the temperature at which it becomes fluid. The temperature at which the bitumen softens and becomes more of less fluid is of considerable importance and arbitrary tests have therefore to be employed. This temperature is called softening point temperature. Higher softening point indicates lower temperature susceptibility and is preferred in warm climates.

Apparatus: Ring and ball apparatus: Brass frame; Beaker; Level glass plate; Steel ball of 10 mm diameter; Spirit lamp

Procedure

- Place the level glass plate in a horizontal platform and apply grease on it.

- Keep the standard ring 16 mm in diameter and 6 mm thick on the glass plate.

- Melt the bitumen and pour it into the standard ring.

- Cool in air for 30 minutes and cut away the excess compound adhering to the ring.

- Place the standard ball of 10 mm diameter at the centre of the bitumen.

- Suspend the whole unit in a beaker of water kept at 5oC with the thermometer bulb and the sample at the same level and at a distance of 12 mm from the sample.

- Apply heat so that rise in temperature is 5oC per minute. Bitumen in the ring melts, the steel ball passes through the test specimen forming a bulb.

- When the bulb reaches 25 mm in depth, note the temperature. This temperature is called softening point temperature.

Note: Softening point temperature for residual and air blown bitumen grade 90 is between 42 and 91 and grade 200 is between 35 and 40oC. For fluxed native asphalt grade 90, it is between 40 and 47oand grade 200, it is between 35 and 45oC.

Flash and Fire-point Test

Flash point of a material is the lowest temperature at which vapour of a substance momentarily taken fire in the form of a flash under specified conditions of lest. Fire point is the lowest temperature at which material gets ignited and bums under specified conditions of test.

Apparatus: Pensky- Martens closed cup apparatus or open cup apparatus Minimum specified flash point of bitumen used in pavement construction in Pensky Martens closed cup type test is 170o

Distillation Tests

These tests are carried out in order to determine characteristic of the materials of same consistencies, since materials having same consistency may have different characteristic. Percentages of the material distilled off at each of the several temperatures and consistency of the residues, give typical characteristics of the materials with the same original consistency.

Procedure

To study effect of heating, an accelerated heating procedure is adopted.

- About 50 g of the sample is weighed and heated to a temperature of 163oC for 5 hours in a special oven designed for this test.

- This specimen is weighed again after the heating period and loss of weight is expressed as a percentage by weight of original sample.

Bitumen used in pavement mixes should not indicate more than one percent loss in weight; for bitumen of penetration values 150-300 upto two percent loss in weight is allowed. Residue after heating when subjected to penetration test shows a reduction in penetration value. Reduction in penetration value should be less then 40 percent of the original penetration value of the bitumen.

TRANSPORTATION ENGINEERING ACE ACADEMY GATE NOTES PDF: CLICK HERE

TRANSPORTATION ENGINEERING MADE EASY GATE NOTES PDF: CLICK HERE

Solubility Tests

Bitumen is the active cementing material of bituminous binders and is solution in carbon disulphide. It is always better to specify some percentage of solubility of materials, so as to avoid any adulteration by the addition of sand, dust or such other impurities. Petroleum products are usually soluble in carbon disulphide up to the extent of 99.5%. Tar contains some organic matter in the form of free carbon, the percentage depending upon the type of coal and the conditions of production. Lake asphalt, out the other hand, has quite a high percentage of inorganic matter Carbon disulphide is very inflammable. Carbon tetrachloride is therefore alternately used to determine the solubility.

A sample of about 2g of bitumen is dissolved in about 100 ml of solvent. The solution is filtered and the insoluble material retained is washed, dried and weighted; it is expressed as a percentage of original sample. The insoluble material should be percentage less than 1.0%. In solubility test with carbon to tetrachloride, if black carbonaceous residue is over 0.5%, the bitumen is considered to be cracked.

Viscosity Test

Viscosity is measure of resistance to flow. There is an optimum value of viscosity, for each aggregate gradation of the mix and bitumen grade. At low viscosity, bituminous binder simply lubricates the aggregate particles instead of providing a uniform film for binding action. Similarly high viscosity also resist the compactive effort and the resulting mix is heterogeneous in character exhibiting low stability values.

Office type viscometer may be used to indirectly find the viscosity of liquid binders like cutback bitumen, emulsion and liquid tar. According to this method, viscosity is measured by determining the time taken by 50 ml of the material to flow from a cup through a specified orifice under standard test conditions and specified temperature. Higher the viscosity of the binder, higher will be the time required.

Float Test

There is a range of consistency of the bituminous materials for which neither an orifice viscometer test nor a penetration test could be used to define the consistency of the material. Consistency of materials of this group is measured by float test.

Specific Gravity Test

Specific gravity of bituminous material is defined as the ratio of the mass of a given volume of the substance to the same of an equal volume of water, the temperature of both being 27C. Specific gravity is determined either by using a pycnometer or by preparing cube shape specimen in semi-solid or solid state and by weighing in air and water. Generally specific gravity of pure bitumen is in the range of 0.97 to 1.02. The specific gravity of cutback bitumen may be lower depending on the type and preparation of diluent used. Tars have specific gravity ranging from 1.10 to 1.25.

Water Content Test

It is desirable that the bitumen contains minimum water content to prevent foaming of the bitumen when it is heated above the boiling point of water. Water content in a bitumen is determined by mixing known weight of the specimen in a pure petroleum distillate free from water heating and distilling off the water. Weight of the water condensed and collected is expressed as a percentage by weight of the original sample. Maximum water content in bitumen should not exceed 0.2 percent by weight.

Spot Test

This test is conducted for detecting over heated or cracked bitumen. This test is considered to be more sensitive than the solubility test for detection of cracking. About 2g bitumen is dissolved in 10 ml of naphtha. A drop of this solution is taken out and placed on a filter paper, on a after one hour and second after 24 hours after the solution is prepared. If stain of the spot on the paper in uniform in colour, the bitumen is accepted as uncracked. But if spots form dark brown or black circle in the centre with an annular ring of lighter colour surrounding it, the bitumen is considered to be overheated or cracked.

TAR It is the viscous liquid obtained when natural organic materials such as wood and coal are carbonised or destructively distilled in the absence of air. Based on the materials from which it is derived, it is classified as follows:

- Wood tar

- Coal tar: It is widely used because it is superior.

Production of Tar

Three stages for production of road tar are as follows:

- Carbonization of coal to produce crude tar.

- Refining a distillation of crude tar

- Blending of distillation residue with distillate oil fraction to give desired road tar.

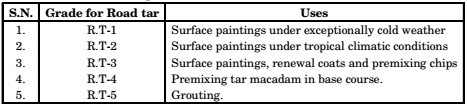

Grades of Road Tar along with their use

Comparison of Bitumen and Tar

- Both bitumen and tar appear blackish in colour when viewed in large masses but appear brown in colour when viewed in thin films.

- Tar coated aggregates exhibit lower stripping action as compared to bitumen coated aggregates.

- Tar is more temperature susceptible, i.e., it becomes liquid at lower temperatures and solidify at comparatively higher ones.

- Tar takes more time to set and therefore a central mixing plant can be used for efficient road construction work.

- Tar is not susceptible to dissolving action of petroleum solvents.

- Tar contains a higher percentage of free- carbon. Therefore it is more brittle- at low temperature.

- Tars may be over heated and spoiled more easily than bitumen.

- Tar takes more time to set. Therefore tar roads take more time before they are opened for traffic.

- Tar contains more phenolic contents and therefore, they get oxidised easily.

- Targets crystallised and forms an internal structure.

Rubber Bitumen

It contains a mixture of bitumen and rubber latex of different forms. This mixture is more resilient than one without. They also serve better to cushion vibrations and traffic shocks. Addition of rubber also increases the softening point and the viscosity of the bituminous mixture. Rubber bitumen mixture is less temperature susceptible. In cold areas the addition of rubber 5.5 to 7% by weight of bitumen reduces surface cracking.

DESIGN OF HIGHWAY PAVEMENTS

Objects and Requirements of Pavements

Objective of a well designed and constructed pavement is to keep elastic deformation of the pavement within the permissible limits, so that pavement can sustain a large number of repeated load applications during design life.

Types of Pavement Structures

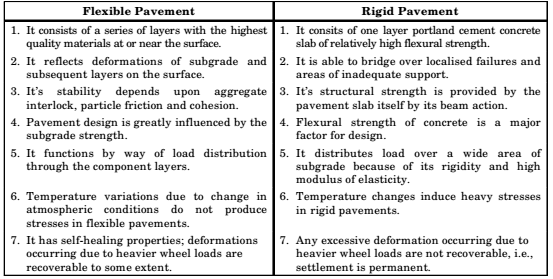

Flexible Pavement

These on the whole have low or negligible flexural strength and are rather flexible in their structural action under the loads. These may be defined as one consisting of a mixture of asphaltic or bituminous material and aggregate placed on a bed of compacted granular material of appropriate quality in layers over the subgrade. It’s design is based on the principle that a load of any magnitude, by carrying it deep enough into the ground through successive layers of granular material, intensity of a load diminishes as the load is transmitted downwards from surface by virtue of spreading over fin increasingly larger area. Consequently, there could be grading in the quality of materials used, materials with a high degree of strength being used error near the surface. Thus, strength of the sub grade primarily influences thickness design of the flexible pavement

Rigid Pavement

These possess no worthy flexural strength or flexural rigidity. It’s design is based on providing a structural cement concrete slab of sufficient strength to resist destructive action of traffic. Because of its rigidity and high modulus of elasticity, it tends to distribute the load over a relatively wide area of soil. Minor variations in subgrade strength have little influence on the structural capacity of a rigid pavement. In the design, flexural strength of concrete is the major factor and not the subgrade strength. It is because of the fact that, when subgrade deflects beneath a rigid pavement, concrete slab is able to bridge over localised failures and areas of inadequate support because of slab action.

Semi-Rigid Pavements

When bonded materials like the pozzolanic concrete (lime-fly ash-aggregate mix), lean cement concrete or soil cement are used in the base course or sub-base course layer, the pavement layer has considerably higher flexural strength than the common flexible pavement layers. However, these bonded materials do not possess as much flexural strength as the cement concrete pavements. Therefore when this intermediate class of materials are used in the base or sub-base course layer of the pavements, they are called semi rigid pavements. These materials have low resistance to impact and abrasion and therefore are usually provided with flexible pavement surface course.

TRANSPORTATION ENGINEERING PART-2 CIVIL ENGINEERING GATE 2020 STUDY MATERIAL FREE DOWNLOAD PDF

DOWNLOAD LINK : CLICK HERE

PASSWORD : CivilEnggForAll

OTHER USEFUL BOOKS

- CIVIL ENGINEERING TEXTBOOKS WITH DOWNLOAD LINKS

- IES MASTER CIVIL ENGINEERING GATE STUDY MATERIALS PDF

- ACE ACADEMY CIVIL ENGINEERING GATE STUDY MATERIALS PDF

- BUILDING MATERIALS – MOCK TEST 1 (QUICK)

- TELANGANA STATE PUBLIC SERVICE COMMISSION – ASSISTANT ENGINEER 2023 – TSPSC AE 2023 CIVIL ENGINEERING EXAM SOLVED PAPER WITH EXPLANATIONS PDF FREE DOWNLOAD

- SSC JE 2023 CIVIL ENGINEERING (CPWD/CWC/MES) EXAM SOLVED PAPER PDF FREE DOWNLOAD

- BIHAR PUBLIC SERVICE COMMISSION ASSISTANT ENGINEER (BPSC AE) 2022 CIVIL ENGINEERING EXAM SOLVED PAPER WITH EXPLANATIONS PDF

- NHPC (NATIONAL HYDROELECTIC POWER CORPORATION) JUNIOR ENGINEER NHPC JE 2022 CIVIL ENGINEERING EXAM SOLVED PAPER PDF FREE DOWNLOAD

Leave a Reply