TOPICS COVERED

- Economic Factors

- Mechanical Properties

- Non-mechanical properties

- Production and construction

- Aesthetic characteristics

- Sustainable design

- Material variability

- Laboratory Measuring devices

- Nature of Materials

- Basic materials concepts

- Metallic Materials

- Inorganic Solids

- Organic Solids

- Steel Production

- Iron-Carbon Phase Diagram

- Heat Treatment of Steel

- Steel Alloys

- Structural Steel

- Cold-Formed Steel

- Fastening Products

- Reinforcing products

- Mechanical Testing of Steel

- Welding

- Steel Corrosion

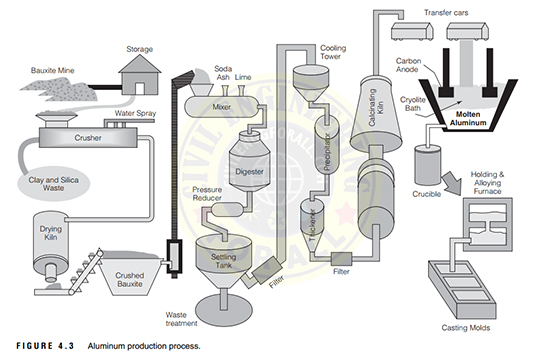

- Aluminium Production

- Aluminium Metallurgy

- Aluminium Testing and Properties

- Welding and Fastening

- Corrosion

- Aggregate Sources

- Geological Classification

- Evaluation of Aggregate Sources

- Aggregate Uses

- Aggregate Properties

- Handling Aggregates

- Portland Cement Production

- Chemical Composition of Portland Cement

- Fineness of Portland Cement

- Specific Gravity of Portland Cement

- Hydration of Portland Cement

- Voids in Hydrated Cement

- Properties of Hydrated Cement

- Water Cement Ratio

- Types of portland cement

- Mixing Water

- Admixtures for cement

- Supplementary Cementitious Materials

- Proportioning of Concrete Mixes

- Mixing, Placing and Handling Fresh Concrete

- Curing Concrete

- Properties of Hardened Concrete

- Testing of Hardened Concrete

- Alternatives to Conventional Concrete

- Masonry Units

- Mortar

- Grout

- Plaster

- Asphalt Products and types

- Uses of Asphalt

- Temperature susceptibility of Asphalt

- Chemical properties of Asphalt

- Superpave and performance grade binders

- Characterization of Asphalt Cement

- Classification of Asphalt

- Asphalt Concrete

- Asphalt Concrete mix design

- Charaterisation of Asphalt Concrete

- Hot Mix Asphalt Concrete Production and Construction

- Recycling of Asphalt Concrete

- Additives

- Warm Mix

- Structure of Wood

- Chemical Composition

- Moisture Content

- Wood Production

- Lumber Grades

- Defects in Lumber

- Physical Properties of Lumber

- Mechanical Properties

- Testing to determine Mechanical properties

- Design Considerations

- Organisms that degrade wood

- Wood Preservation

- Engineered wood products

- Microscopic composites

- Macroscopic composites

- Properties of composites

Materials Engineering

Materials engineers are responsible for the selection, specification, and quality control of materials to be used in a job. These materials must meet certain classes of criteria or materials properties. These classes of criteria include

- economic factors

- mechanical properties

- nonmechanical properties

- production/construction considerations

- aesthetic properties

In addition to this traditional list of criteria, civil engineers must be concerned with environmental quality. In 1997 the ASCE Code of Ethics was modified to include “sustainable development” as an ethics issue. Sustainable development basically recognizes the fact that our designs should be sensitive to the ability of future generations to meet their needs. There is a strong tie between the materials selected for design and sustainable development. When engineers select the material for a specific application, they must consider the various criteria and make compromises. Both the client and the purpose of the facility or structure dictate, to a certain extent, the emphasis that will be placed on the different criteria. Civil and construction engineers must be familiar with materials used in the construction of a wide range of structures. Materials most frequently used include steel, aggregate, concrete, masonry, asphalt, and wood. Materials used to a lesser extent include aluminum, glass, plastics, and fiber-reinforced composites. Geotechnical engineers make a reasonable case for including soil as the most widely used engineering material, since it provides the basic support for all civil engineering structures. However, the properties of soils will not be discussed in this text because soil properties are generally the topic of a separate course in civil and construction engineering curriculums.

DOWNLOAD IES MASTER GATE MATERIALS : CLICK HERE

Recent advances in the technology of civil engineering materials have resulted in the development of better quality, more economical, and safer materials. These materials are commonly referred to as high-performance materials. Because more is known about the molecular structure of materials and because of the continuous research efforts by scientists and engineers, new materials such as polymers, adhesives, composites, geotextiles, coatings, cold-formed metals, and various synthetic products are competing with traditional civil engineering materials. In addition, improvements have been made to existing materials by changing their molecular structures or including additives to improve quality, economy, and performance. For example, superplasticizers have made a breakthrough in the concrete industry, allowing the production of much stronger concrete. Joints made of elastomeric materials have improved the safety of high-rise structures in earthquake-active areas.

Lightweight synthetic aggregates have decreased the weight of concrete structures, allowing small cross-sectional areas of components. Polymers have been mixed with asphalt, allowing pavements to last longer under the effect of vehicle loads and environmental conditions. The field of fiber composite materials has developed rapidly in the last 30 years. Many recent civil engineering projects have used fiber-reinforced polymer composites. These advanced composites compete with traditional materials due to their higher strength-to-weight ratio and their ability to overcome such shortcomings as corrosion. For example, fiber-reinforced concrete has much greater toughness than conventional portland cement concrete. Composites can replace reinforcing steel in concrete structures. In fact, composites have allowed the construction of structures that could not have been built in the past. The nature and behavior of civil engineering materials are as complicated as those of materials used in any other field of engineering. Due to the high quantity of materials used in civil engineering projects, the civil engineer frequently works with locally available materials that are not as highly refined as the materials used in other engineering fields. As a result, civil engineering materials frequently have highly variable properties and characteristics.

DOWNLOAD ACE GATE MATERIALS : CLICK HERE

Steel Production

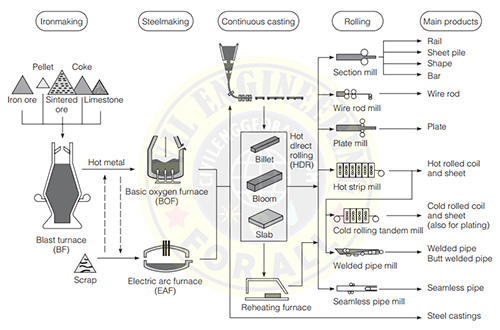

This process consists of the following three phases:

- reducing iron ore to pig iron

- refining pig iron (and scrap steel from recycling) to steel

- forming the steel into products

The materials used to produce pig iron are coal, limestone, and iron ore. The coal, after transformation to coke, supplies carbon used to reduce iron oxides in the ore. Limestone is used to help remove impurities. Prior to reduction, the concentration of iron in the ore is increased by crushing and soaking the ore. The iron is magnetically extracted from the waste, and the extracted material is formed into pellets and fired. The processed ore contains about 65% iron. Reduction of the ore to pig iron is accomplished in a blast furnace. The ore is heated in the presence of carbon. Oxygen in the ore reacts with carbon to form gases. A flux is used to help remove impurities. The molten iron, with an excess of carbon in solution, collects at the bottom of the furnace. The impurities, slag, float on top of the molten pig iron The excess carbon, along with other impurities, must be removed to produce high-quality steel. Using the same refining process, scrap steel can be recycled. Two types of furnaces are used for refining pig iron to steel are basic oxygen and electric arc.

DOWNLOAD MADE EASY GATE NOTES : CLICK HERE

The basic oxygen furnaces remove excess carbon by reacting the carbon with oxygen to form gases. Lances circulate oxygen through the molten material. The process is continued until all impurities are removed and the desired carbon content is achieved. Electric furnaces use an electric arc between carbon electrodes to melt and refine the steel. These plants require a tremendous amount of energy, and are used primarily to recycle scrap steel. Electric furnaces are frequently used in minimills, which produce a limited range of products. In this process, molten steel is transferred to the ladle. Alloying elements and additional agents can be added either in the furnace or the ladle. During the steel production process, oxygen may become dissolved in the liquid metal. As the steel solidifies, the oxygen can combine with carbon to form carbon monoxide bubbles that are trapped in the steel and can act as initiation points for failure. Deoxidizing agents, such as aluminum, ferrosilicon and manganese, can eliminate the formation of the carbon monoxide bubbles. Completely deoxidized steels are known as killed steels. Steels that are generally killed include:

- Those with a carbon content greater than 0.25%

- All forging grades of steels

- Structural steels with carbon content between 0.15 and 0.25 percent

- Some special steel in the lower carbon ranges

Regardless of the refining process, the molten steel, with the desired chemical composition, is then either cast into ingots (large blocks of steel) or cast continuously into a desired shape. Continuous casting with hot rolling is becoming the standard production method, since it is more energy efficient than casting ingots, as the ingots must be reheated prior to shaping the steel into the final product. Cold-formed steel is produced from sheets or coils of hot rolled steel which is formed into shape either through press-braking blanks sheared from sheets or coils, or more commonly, by rollforming the steel through a series of dies. No heat is required to form the shapes (unlike hot-rolled steel), and thus the name cold-formed steel. Cold-formed steel members and other products are thinner, lighter, and easier to produce, and typically cost less than their hot-rolled counterparts.

BUILDING MATERIALS AND CONSTRUCTION TEXTBOOK BY CIVILENGGFORALL

DOWNLOAD LINK : CLICK HERE

PASSWORD : CivilEnggForAll

OTHER USEFUL BOOKS

- RAJASTHAN STAFF SELECTION BOARD (RSSB) JUNIOR ENGINEER DIPLOMA CIVIL ENGINEERING EXAM 2022 – HINDI & ENGLISH MEDIUM SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ISRO TECHNICAL ASSISTANT EXAM 2022 – CIVIL ENGINEERING – HINDI & ENGLISH MEDIUM – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- MADHYA PRADESH PUBLIC SERVICE (MPPSC) COMMISSION – ASSISTANT ENGINEER EXAM – MPPSC AE 2021 CIVIL ENGINEERING – SOLVED PAPER WITH EXPLANATIONS – PDF FREE DOWNLOAD

- BIHAR PUBLIC SERVICE COMMISSION (BPSC) ASSISTANT ENGINEER EXAM – 2022 – CIVIL ENGINEERING – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ODISHA PUBLIC SERVICE COMMISSION – OPSC AEE PANCHAYATI RAJ EXAM 2021 – SOLVED PAPER WITH EXPLANATION – FREE DOWNLOAD PDF