TOPICS COVERED

- Introduction to Railway Engineering

- Station Layout

- Rolling Stock

- Depots and Workshops

- Tracks

- Earthworks, Drainage and Fencing

- Bridges and Structures

- Tunnels and Tunneling

- Electrification

- Signalling and Train Control

- Systems and Communications

- Lifts, Escalators and Pumps

- Ventilation and Drought Relief

- Future Trends

INTRODUCTION TO RAILWAY ENGINEERING

In medieval times people mostly travelled by foot or horseback and any form of transportation was mainly for moving goods. The first railways were laid down in the seventeenth and eighteenth century for horse drawn trains of wagons in collieries and quarries. These ‘hauling ways’ initially had a surface of stone slabs or timber baulks which soon proved unsatisfactory as the loads carried inevitably grew heavier. As the Industrial Revolution progressed, the idea was developed further by adding cast iron or wrought iron plates to reduce wear on the wooden baulks. This evolved further to iron edge rails enabling the use of flanged wheels for the first time. By the time steam locomotives came on the scene, in the early nineteenth century, wrought iron rails and later steel rails were developed which were strong enough to support these heavy axle loads without assistance from longitudinal timbers. In essence the track itself, together with its supports, had and still has the basic function of safely transmitting the loads and forces imposed by passing trains to the ground beneath. Various other civil engineering skills were also involved in the construction of early railways. These included the building of bridges, tunnels and gravity walls as well as extensive earthworks and drainage. From these earliest days, there was a need to balance the requirements and interests of the various engineering disciplines involved. As an example, rolling stock design has a considerable impact on the design and maintenance of the fixed infrastructure and there needs to be mutual appreciation and close co-operation between engineers if the best is to be achieved in all areas. This may sometimes require compromise in certain disciplines for the good of the whole.

HIGHWAY ENGINEERING IES MASTER GATE MATERIAL : CLICK HERE

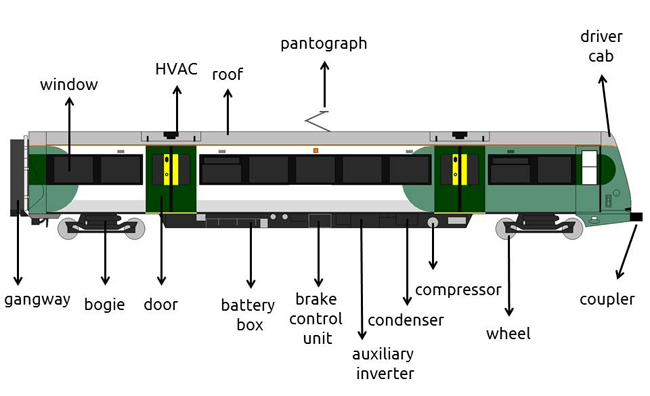

RAILWAY ROLLING STOCK

It is always useful at the outset of consideration of a subject to pause for a moment and to ponder the definitions, attributes range and scope of the matter. Rolling stock used on railways in the earliest days evolved from carriages and wagons which ran on highways to carry both people and bulk materials. As early as the sixteenth century wooden wheeled carts were used in mines and quarries running on longitudinal timber rails. With the progressive evolution of the skills and crafts of the wheelwright, metalworker and the ironmaker, wheels improved through various phases from simple rough turned wooden spools through spoked and rimmed construction to fully cast and turned metal wheels.Similarly, body construction and springing, particularly for passenger carrying vehicles, relied very heavily on the experience gained in the construction of stagecoaches in the seventeenth and eighteenth centuries. At the end of the eighteenth century, horse drawn trams running on metal rails began to appear in a number of European cities. These horse drawn tramways were literally to pave the way for development of railways when steam power began to be developed early in the 1800’s. One has only to look at illustrations of early passenger coaches to see how closely they resemble the road vehicles of the previous century.

TRANSPORTATION ENGINEERING ACE GATE NOTES : CLICK HERE

BALANCE BETWEEN WORKSHOPS AND DEPOTS

Originally railway companies set up both railway workshops and railway depots on their systems. As practically all the engineering work was done ‘in-house’, the scope of activities was very wide and depots and workshops had very differing functions. In many cases, the early railway companies manufactured their own locomotives and rolling stock and carried out all major repairs and refitting in the same works. The practice has gradually changed over the years and now most manufacture and major overhaul is carried out by independent suppliers. Railways therefore need to carefully consider what engineering activities still need to be carried out on their own premises and by their own staff. Having decided this, it is a short step to a decision as to what operations are most sensibly carried out at a depot and which are better done at a separate workshop location. On many railways, depots contain a minimum of workshop facilities for day-to-day maintenance and unit/component changing, the major work being carried out elsewhere by tendered contract, either by supplier or ‘in-house’.

BASIC COMPONENTS OF TRACK

Today most railway share rolling stock with hard steel flanged wheels running on two rails set at or about 1432 mm standard gauge, supported in some way to spread loads to the ground below. ‘Sub-grade’is the term used for the natural soil stratum, or embankment soil, after trimming off organic topsoil and made ground, upon which the track bed is constructed. The ‘Trackbed’ comprises the ballast and any sub-ballast layers and is there to support the track, to drain water from the bottom of the sleepers and to distribute the imposed track load to such a degree that the sub-grade can resist the imposed bearing pressure adequately.

TRANSPORTATION ENGINEERING MADE EASY GATE NOTES : CLICK HERE

SLEEPER FUNCTIONS

Sleepers and bearers or timbers (for points and crossings) need to fulfil the following basic functions:

- Spread wheel loads to ballast

- Hold rails to gauge and inclination

- Transmit lateral and longitudinal forces

- Insulate rails electrically

- Provide a base for rail seats and fastenings

Sleepers are also often called upon to fulfil other secondary but important functions which should not be overlooked. These include:

- Supporting wheels and/or jacks direct (in a derailment situation)

- Acting as transverse beams when sitting on temporary ‘waybeams’

- Supporting signal engineering and other safety related equipment

- Supporting conductor rails, electrical bonds and feeder cables

- Reducing noise and vibration on non-ballasted bridge decks

RAILWAY ENGINEERING TEXTBOOK BY CIVILENGGFORALL PDF

DOWNLOAD LINK : CLICK HERE

PASSWORD : CivilEnggForAll

OTHER USEFUL BOOKS

- RAJASTHAN STAFF SELECTION BOARD (RSSB) JUNIOR ENGINEER DIPLOMA CIVIL ENGINEERING EXAM 2022 – HINDI & ENGLISH MEDIUM SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ISRO TECHNICAL ASSISTANT EXAM 2022 – CIVIL ENGINEERING – HINDI & ENGLISH MEDIUM – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- MADHYA PRADESH PUBLIC SERVICE (MPPSC) COMMISSION – ASSISTANT ENGINEER EXAM – MPPSC AE 2021 CIVIL ENGINEERING – SOLVED PAPER WITH EXPLANATIONS – PDF FREE DOWNLOAD

- BIHAR PUBLIC SERVICE COMMISSION (BPSC) ASSISTANT ENGINEER EXAM – 2022 – CIVIL ENGINEERING – SOLVED PAPER – FREE DOWNLOAD PDF (CivilEnggForAll.com)

- ODISHA PUBLIC SERVICE COMMISSION – OPSC AEE PANCHAYATI RAJ EXAM 2021 – SOLVED PAPER WITH EXPLANATION – FREE DOWNLOAD PDF